Meet MITO

All your business

on one platform.

Simple, efficient, yet affordable!

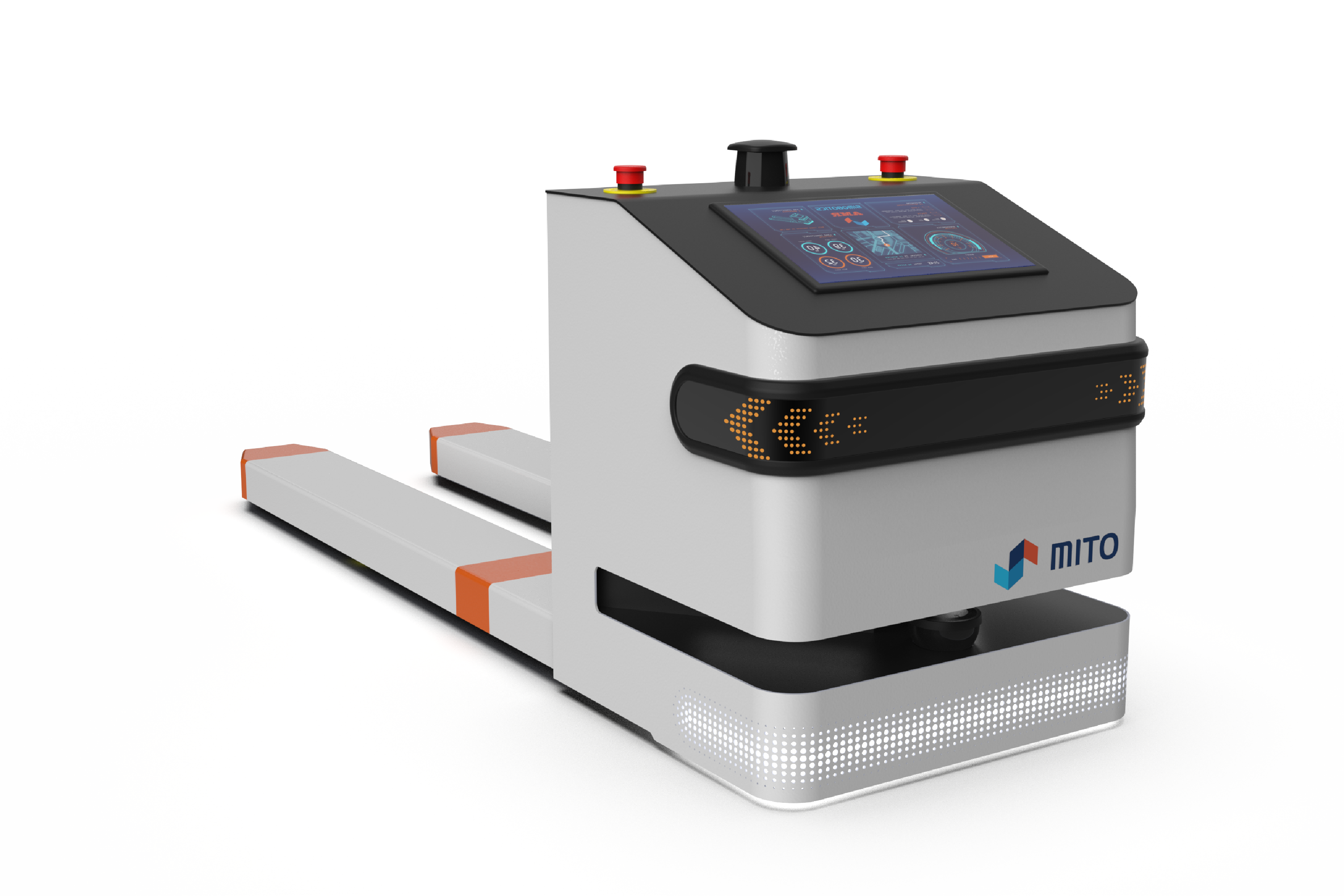

Autonomous mobile robot/AMR

First of its kind

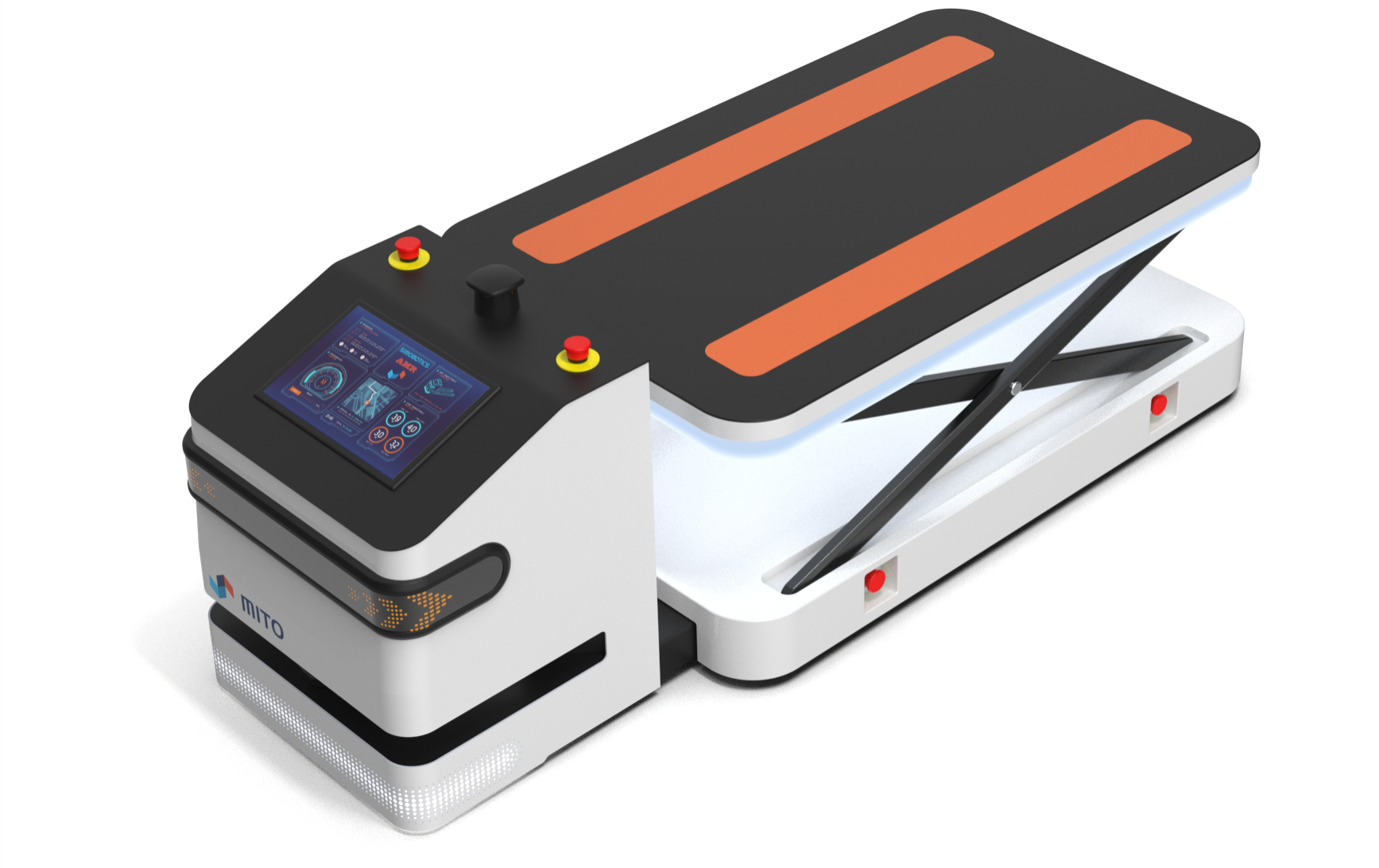

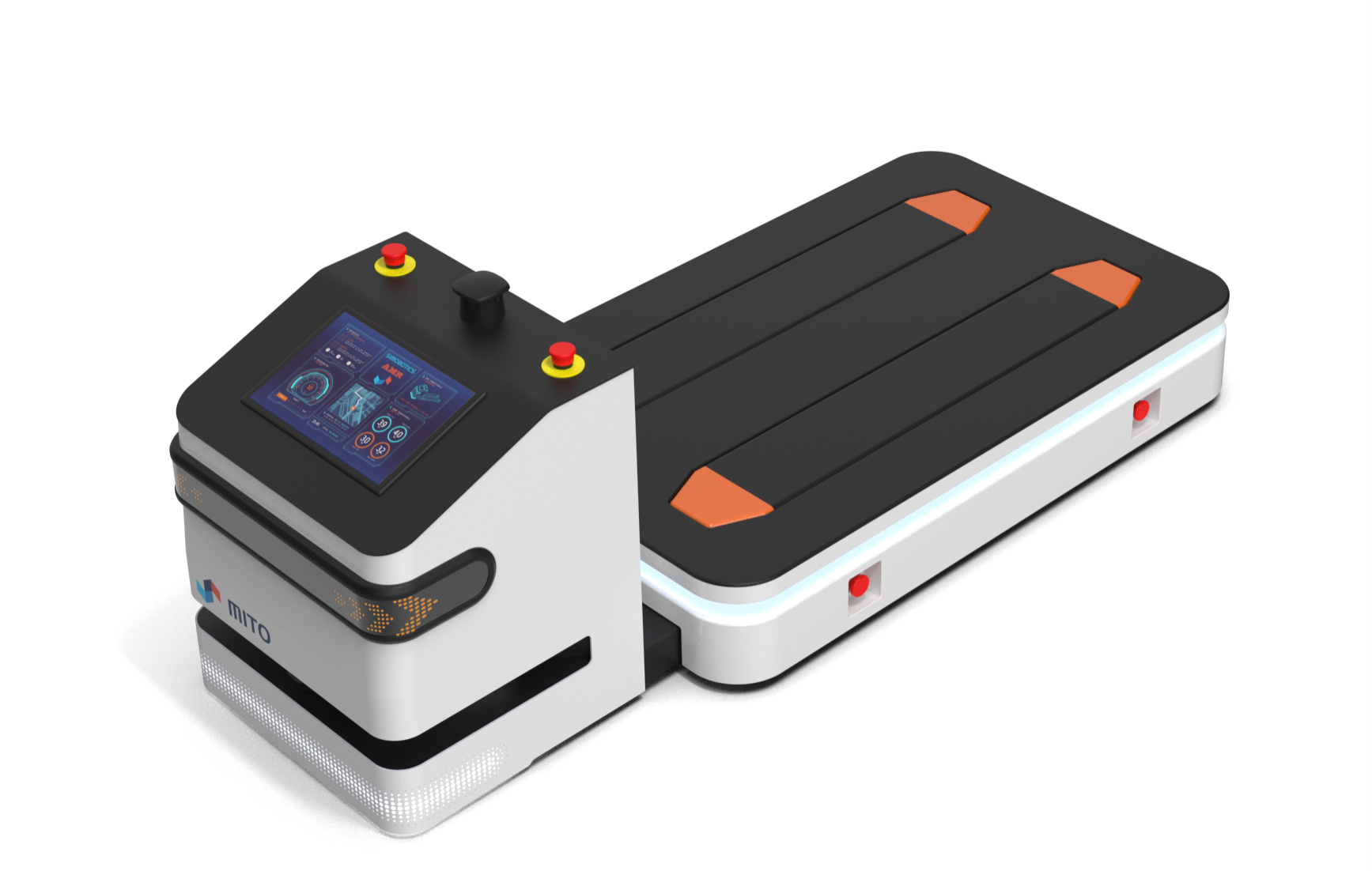

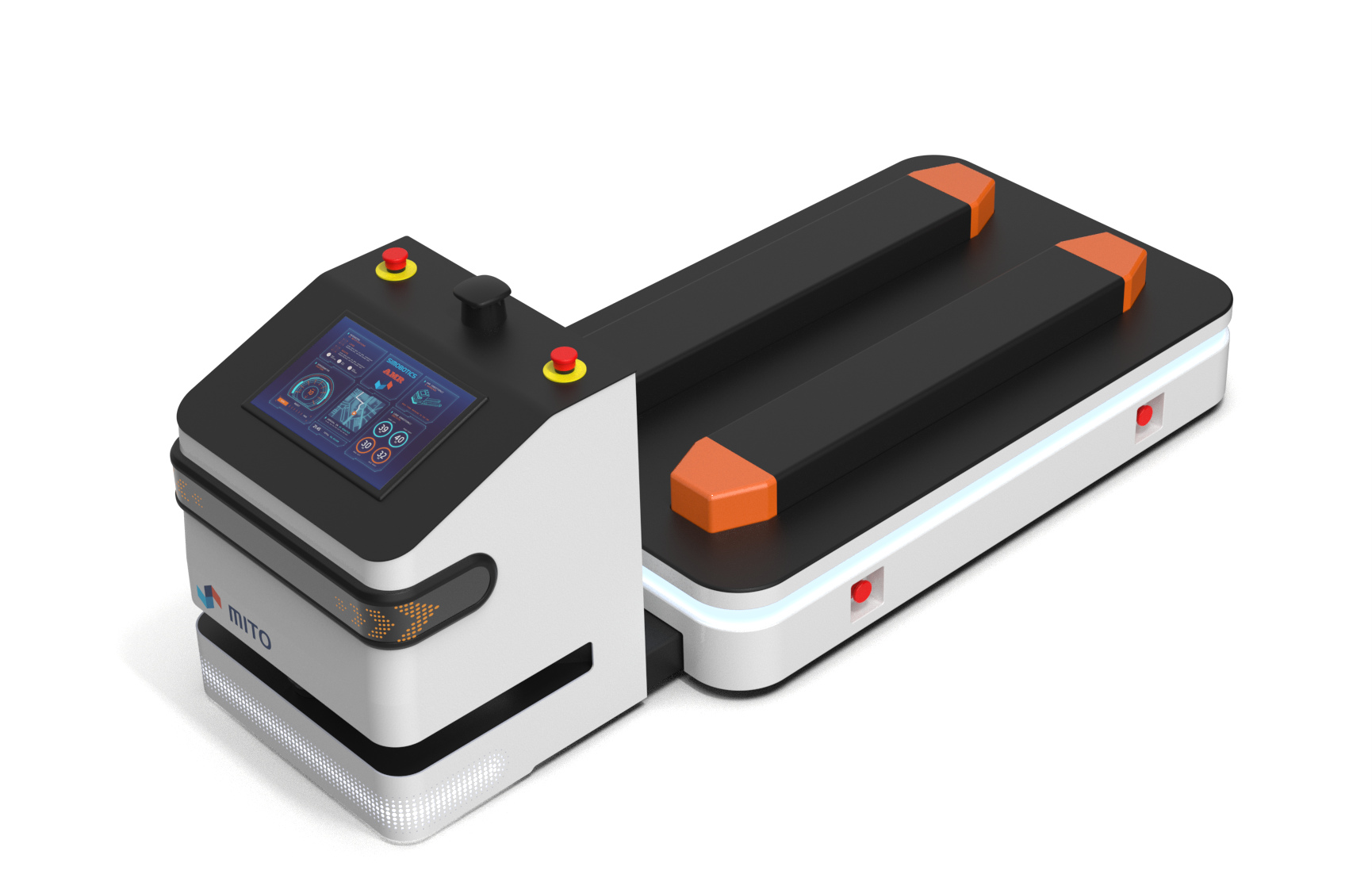

AMHR - autonomous multi-handling robot

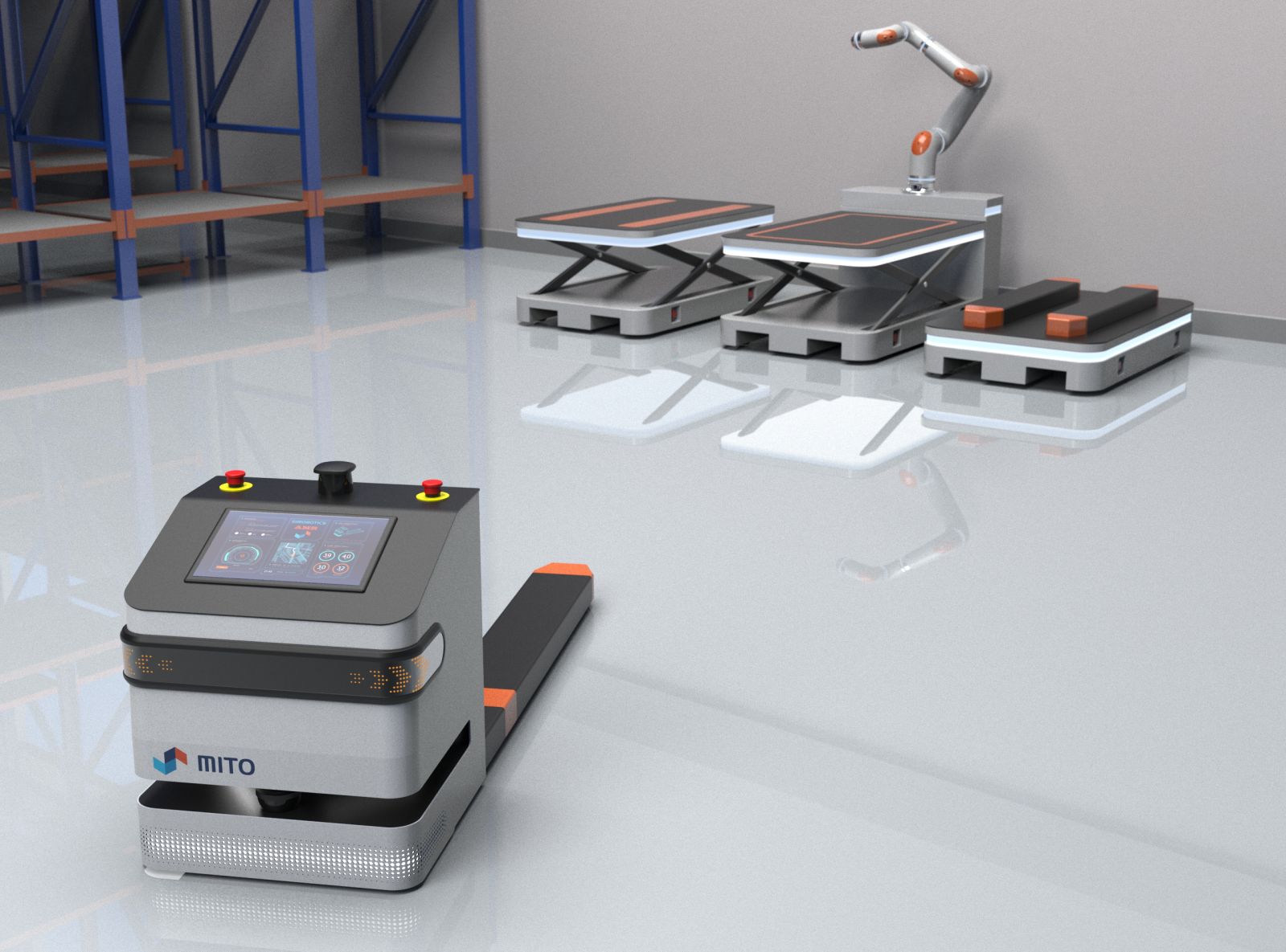

Versatile use cases

AMHR is using in Automotive, Food&Beverage, Healthcare&Pharma, Packaging, Paper and Printing, Production and many more sectors. AMHR has roles, such as: Moving finished products from the end of production lines to warehouses. Supplying raw materials from warehouses to production lines. Transferring work-in-progress materials between production steps or using itself as production lines, replacing transitional chains and conveyors. Using in warehouses and distribution centres as Picking zone, G2P, piece-picker or flexible sortation and many more.

Pallet Truck

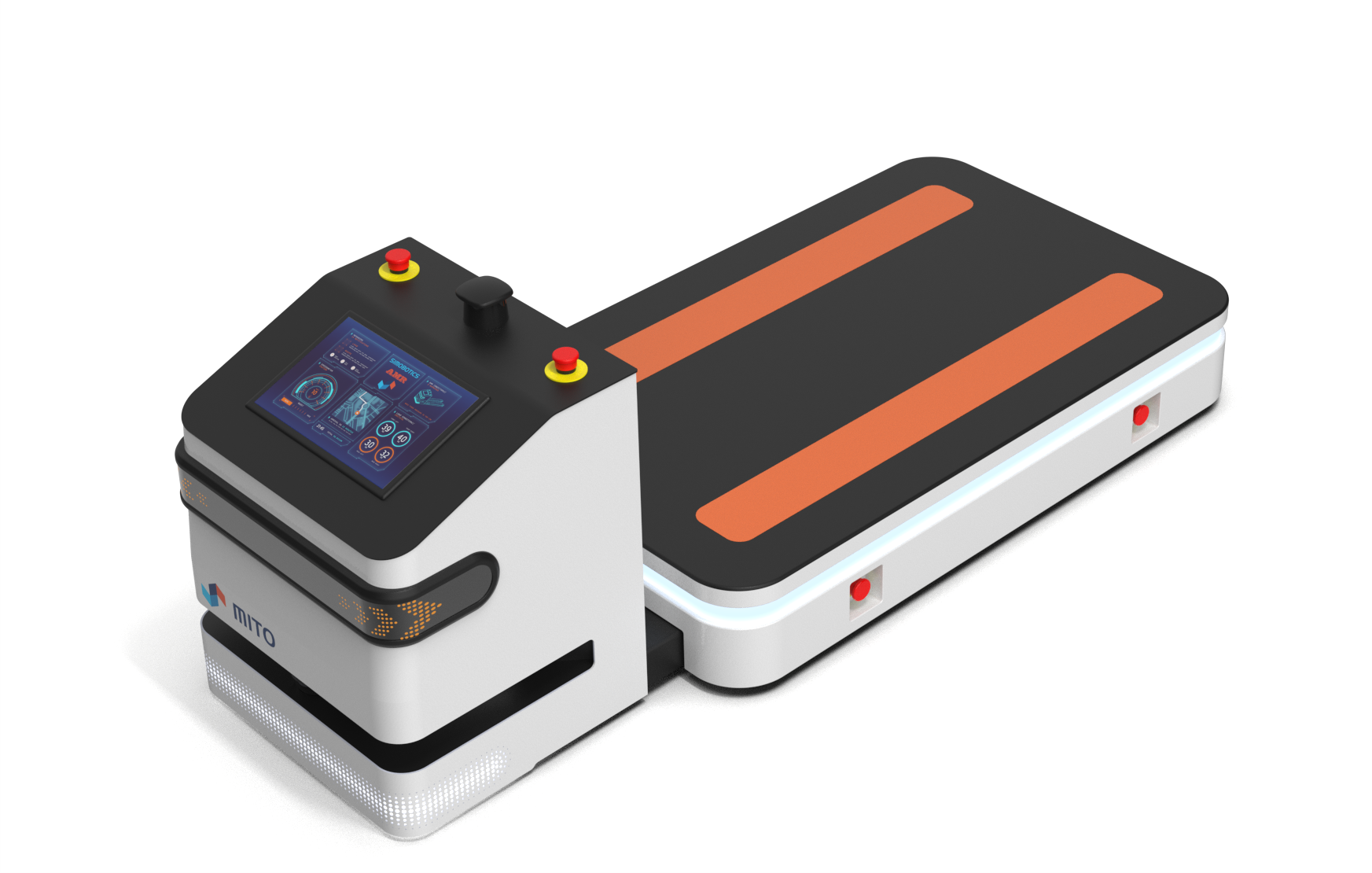

Stationary Platform

Lifting Platform

Lifting Rails

Pallet Lifting

Pick & Place Platform

Pick & Place Lifting

Shelf Platform

Roller/Conveyor Platform

Roller/Conveyor Pick & Place Platform

Deployment in less than a day

Simple, Safe, Scalable Multi-purpose Platform

-

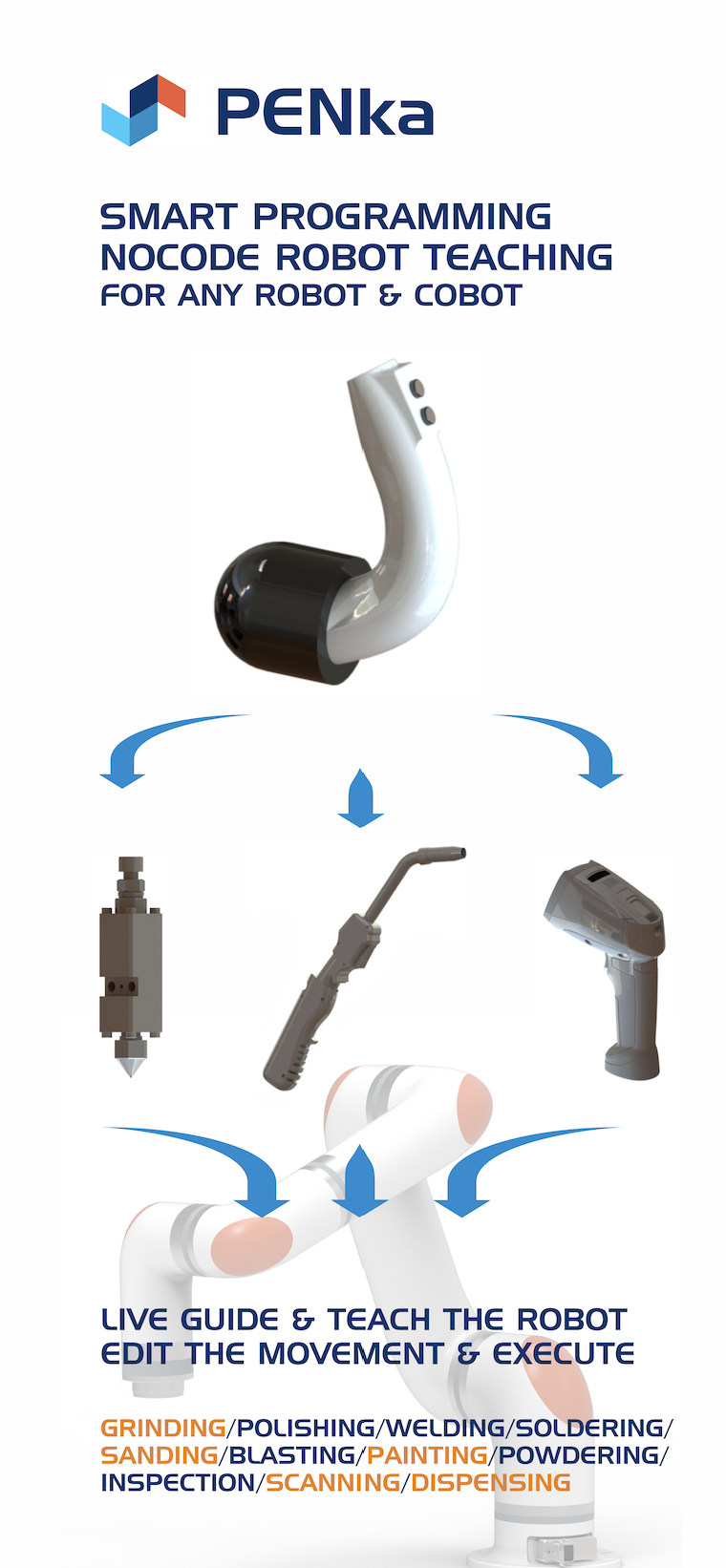

No code, nice user interface allows drag & drop, graphical programming on shopfloor

-

Digital twin, intuitive simple interface

-

AI ecosystem, hides complexity

-

Versatile, flexible, modular platform based solution

-

Fleet management system according VDA 5050

-

Safety standard PLd/SIL2

-

Autonomous localisation & navigation system, obstacles avoidance

-

Fast charging: 12 minutes for 8 hours of typical operation